Fire Protection Industry

A brief overview of the fire protection industry and the different methods and products used for fire protection in construction today.

United Spray

In recent years, the demand and focus on sustainable construction has gained growing interest. There has been

remarkable promotion for sustainable construction in the industry and encouragement for the use of sustainable

materials such as wood, steel and recycled materials.

However, a major concern that has arisen with the use of such material is the level of fire protection provided

and the ability of structures in general to withstand damage from a sudden fire, fires can spark in seconds and

result in serious damage to structures and result in casualties of occupants. With this is mind, fire safety

engineering has gained wide popularity in building design and has become mandatory and essential in all types

of structures.

Based on the type of material used in the construction and final occupancy of the building, different fire

resistance ratings 1 requirements exist for these buildings’ components and can be achieved through different

means.

In some types of structures, fire safety and protection can be achieved through adequate use of incombustible

materials in the main structural frame, i.e., steel, concrete, aggregates, as guided by codes and standards.

However, in structures where high fire ratings are required, the incorporation of protection systems is mandatory

since the use of such incombustible materials by themselves would not be able to sustain the potential fire risk.

Fire protection systems have two main objectives. The first is to detect and suppress the fire through what is

known as active systems, that include automatic smoke and heat detection and sprinklers systems. The

second is to contain and delay the spread of fire and failure of building components, which could be done

through the incorporation of passive protection systems such as applied protective coating and fire protection

barriers.

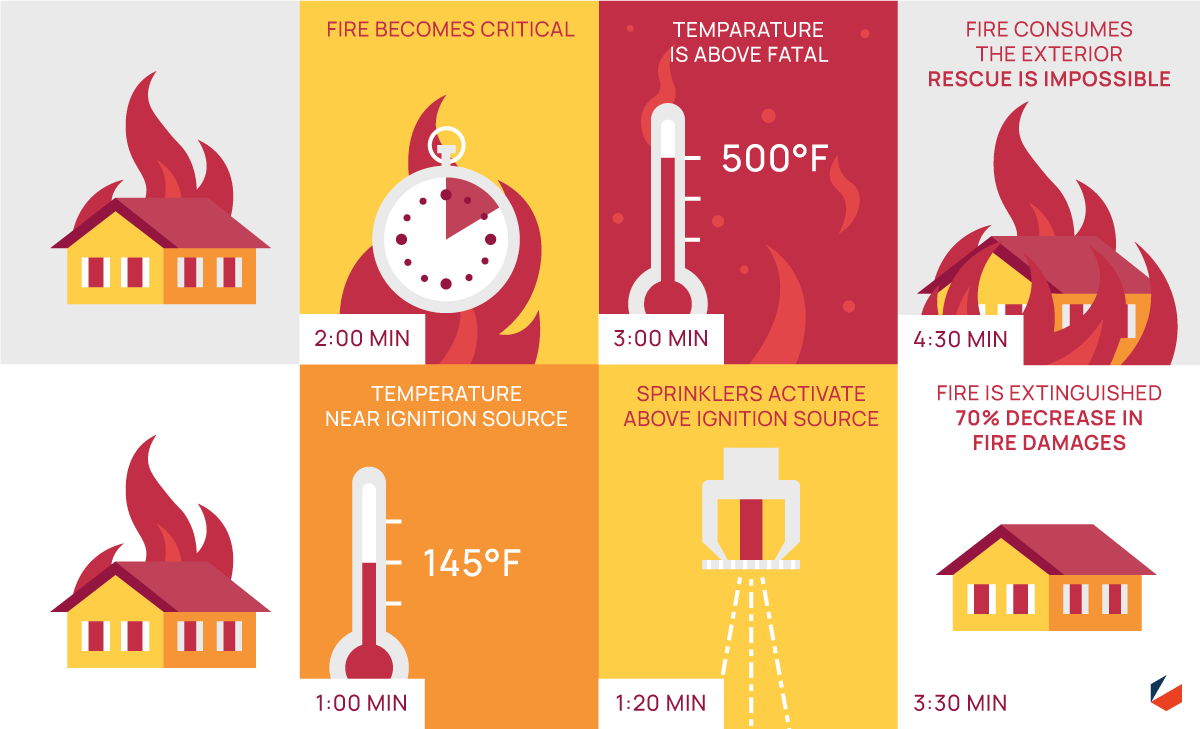

Unlike small residential projects where simple insulation (i.e.: Spray Foam) and small detection systems are used, sprinklers and passive protection systems are widely adopted in large structures such as schools, hospitals, multi-family, warehouses, off-shore petroleum platforms, malls and many others, where the fire protection requirements are of great importance due to difficulty of occupant egress.

How sprinkler systems work and their effectivity

According to the National Fire Protection Association, “Automatic sprinklers are highly effective and reliable elements of total system designs for fire protection in buildings.” A fire sprinkler system can reduce or even prevent fire damage in case of fire, as well as minimize chances of injury to customers, tenants and other people present. There are a few common misconceptions about how sprinkler system work, how they are activated and if they produce great water damage to the property.

How sprinklers are activated

Contrary to popular belief, fire sprinklers are not triggered by smoke. Most of the sprinklers heads feature a glass bulb, which contains a glycerin-based liquid, that expands when in contact with 135 to 165 degrees Fahrenheit heated air. As the liquid expands it breaks the glass and the sprinkler is activated.

Fire sprinklers and water damage

Another common misconception is that fire sprinklers cause a great amount of water damage, that all sprinklers work together in a system and when one is triggered by the heated air — all activate in the same time. This is not how the sprinkler system works. Each sprinkler head functions individually, as most of the time fires can be completely extinguished by one to two active sprinklers. In this case, the water damage is confined to the ignition source.

Are fire sprinklers effective

According to the research conducted by NFPA, fire sprinklers save lives, with the data showing that the civilian fire death rate was 87% lower in properties with sprinklers than in properties with no AES. Apart from plummet in death rates , the civilian injury also show downward trend, the civilian injury rate per 1,000 reported fires was 27% lower in properties with sprinklers than in properties with no AES.

To learn more about research at NFPA visit www.nfpa.org/research

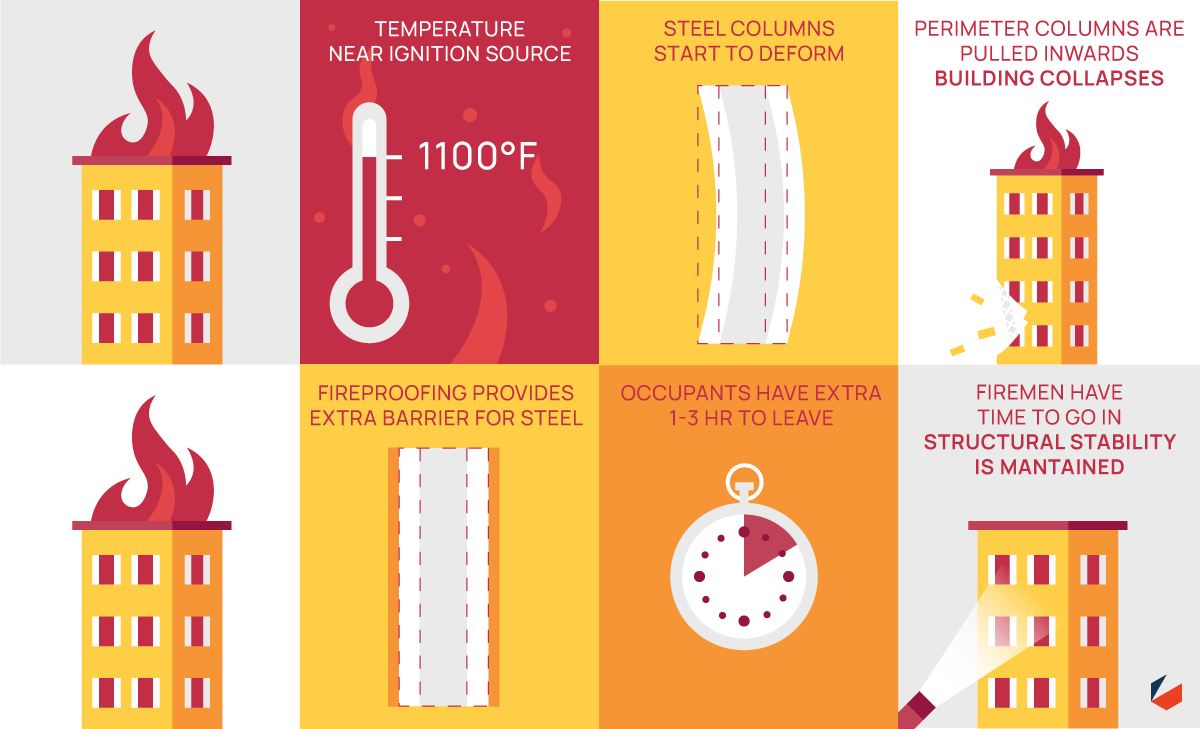

Fire Protection for Steel Structures

Steel the other hand, despite its rigidity and high load bearing capacities is relatively vulnerable to fire and its failure is inevitable under high temperatures. Theoretically, the critical temperature at which the steel structure is at risk of losing its stability is around 500 C (932 F), while in general, the temperature on site could reach up to 1000 C (1832 F). At such high temperatures, the steel will lose its strength and due to the release of inner stress, it will transfer from elastic to plastic deformation state, hence resulting in local failure of structural members and in extreme cases to the collapse of the overall structure, which emphasizes the importance of fire protection is such structures. In order to achieve the required fire resistance of these structures, as mentioned above, several protection techniques are adopted, such as Spray-Applied Fire-Resistive Material (SFRM), Intumescent Paint and Board Protection.

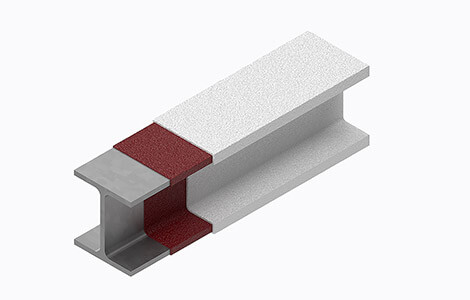

Spray-Applied Fire-Resistive Materials (SFRMs)

SFRMs are composed a combination of binding agents such a cement or gypsum and often other materials such as mineral wool, quartz, perlite, bauxite or vermiculite. They are available as a wet or dry spray formula and are delivered as a dry powder in a bag, which is mixed with water in the field. They are typically sprayed but some can also be trowel applied.

Intumescent Paints (IFRMs)

IFRMs are another form of coating that expands when exposed to high temperatures. They are usually used when a smooth and aesthetically pleasing finish is required along with fire protection and they can be applied to the structural members utilizing customary painting techniques such as spraying, rolling or brushing.

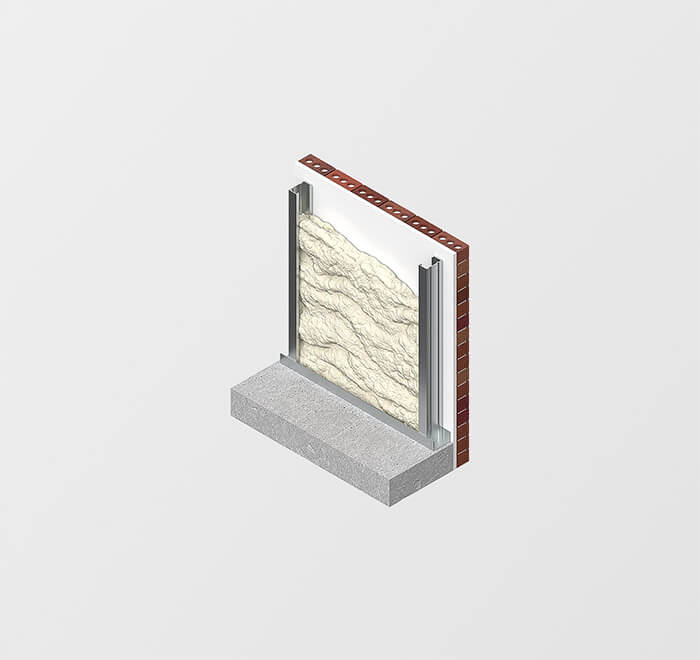

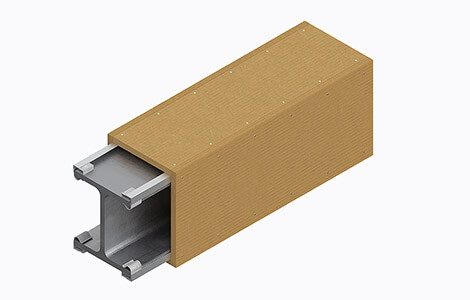

Board Protection

Fireproofing board is another form of widely used solution for fire protection. Usually the structural member is fully enclosed within a fire board box as shown in figure 8. Such boards are usually made from calcium silicate or gypsum plaster with thicknesses varying from 15 mm to 30 mm thick that could provide up to 4 hour fire rating.

Conclusion

The application of these materials is crucial, since the misapplication of fire protection could result in long-term poor performance which could result in serious structural damage and large losses. For that reason, materials must be installed in accordance with regulatory and testing agencies standards that govern the application details such as mixing techniques, thickness of application and properties of materials used. These standards are obtained as a result of extensive testing of materials and assemblies, such as the ASTM E119/UL 263 which are the standards for testing of materials for cellulosic fire (general form of fire in residential/commercial structures) and ASTM E1529/ UL1709 which are the standards for testing materials for hydrocarbon fire (general form of fire which is induced by petroleum products). As it has been determined, fire protection is a crucial part for structures and businesses in general, since any fire could spark and spread in minutes, leaving behind severe damage, which could result in millions of dollars of losses in inventories and expensive equipment, in addition to human casualties and potential loss of business.