-

01

Cost Effective Solution

Budget friendly option to meet building codes

-

02

Quick Installation Relative to Other Products

Saves time and moves project towards completion

-

03

Prolongs Structural Integrity

Gives occupants & emergency responders valuable time in case of fire

-

04

Exterior Grade Available

For areas where weather exposure is likely to occur

United Spray in Action

Our crews have experience in completing projects of all sizes and logistical complexities. From pre-construction planning through installation and project closeout, we strive to exceed our clients expectations in every way. Fireproofing is an integral part of life safety in modern buildings and it is important to hire a professional with the right experience.

United Spray continuously invests in the latest fireproofing equipment and employee training to ensure we give our clients the best possible final product.

Types of projects

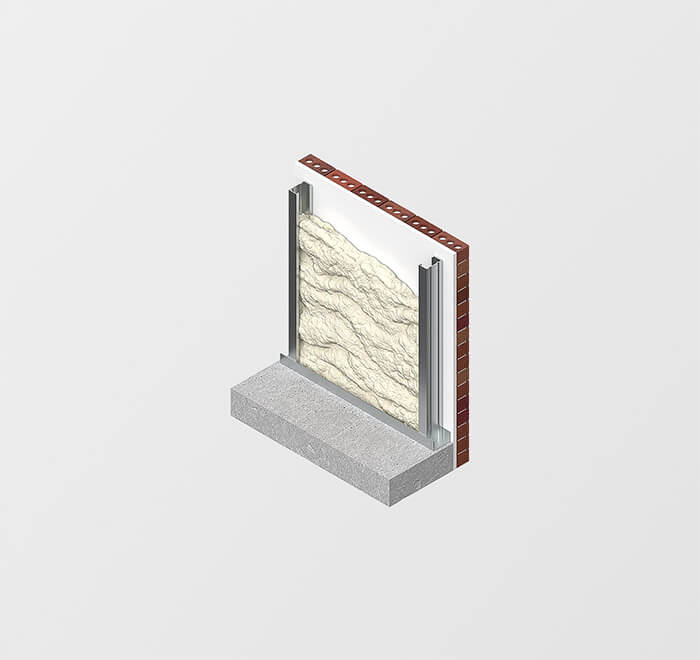

Spray Fireproofing can be found in many different types of steel framed buildings. Commercial and industrial construction projects can all benefit from Spray-Applied Fireproofing no matter the end use.

- Tunnels

- High Rise Buildings

- Equipment Rooms

- Manufacturing Plants

- Roof Decks

- Structural Steelwork

- Concealed Interior Structures

- Parking Garages

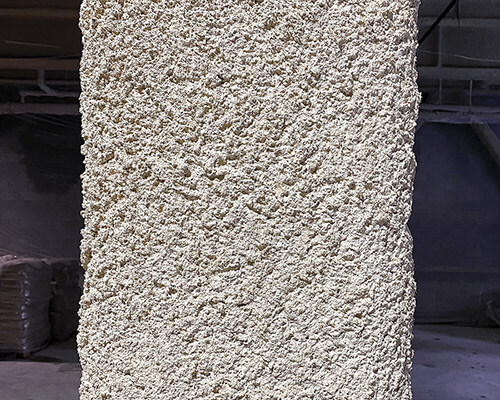

Spray Applied Fireproofing Performance Overview

Product Testing

All of the products that we offer have undergone rigorous testing by both ASTM and Underwriters Laboratory (UL) to verify their physical properties and determine their performance during a fire. UL fire tests are conducted on various construction assemblies and data is used to extrapolate a required thickness for each individual steel member based on the required hourly rating. Selection of the proper UL design for each project is critical in insuring that a building meets codes.

Technical Data

ASTM Standards

- ASTM E 605 Density

- ASTM E 736 Cohesion / Adhesion (Bond Strength)

- ASTM E 761 Compression

- ASTM E 84 Surface Burning Characteristics

- ASTM E 937 Corrosion

- ASTM G 21 Fungal Resistance

UL Designs (Floor/Ceiling)

- Floor Assemblies D925, D739, D759, D743, D779, D780, D782, D859, D902, D985, G705

- Floor Beams N706, N708, N743, N759, N761, N777, N779, N782, N784, N792, N854

- Concrete Decks J701, J708, J709, J710, J712, J809, J957

UL Designs (Roof)

- Roof Assemblies P714, P719, P723, P725, P732, P733, P740, P819, P825, P826, P908, P936

- Roof Beams S721, S728, S729, S734, S735, S749, S750

- Tube & Pipe Y710, X790, X795

UL Designs (Column)

Column X790, X795, X827, X829, X854, XR711, XR715, XR731, Y710

Manufacturers and Products

United Spray takes pride in working with the best available materials and manufacturers

For a full list of spray foam used

Fireproofing SolutionsPREVIOUS

Board FireproofingNEXT

Intumescent Coating