-

01

No Temperature Requirements for Installation

When adverse weather conditions prevent installation of other products

-

02

Long Lasting Performance

Little to no deterioration of product over time

-

03

No Chance of Flaking or Spalling

For sensitive areas where cleanliness is key

-

04

No Surface Prep Required

Acceptable to install over oily or rusted surface

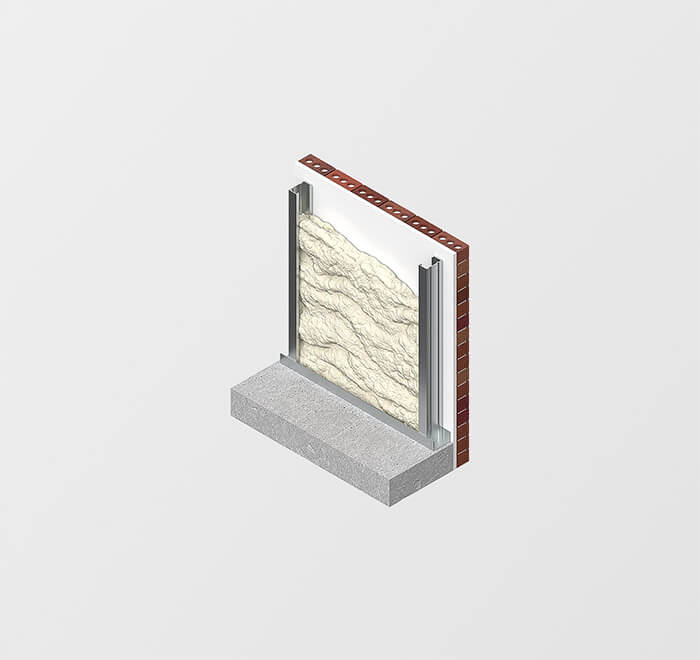

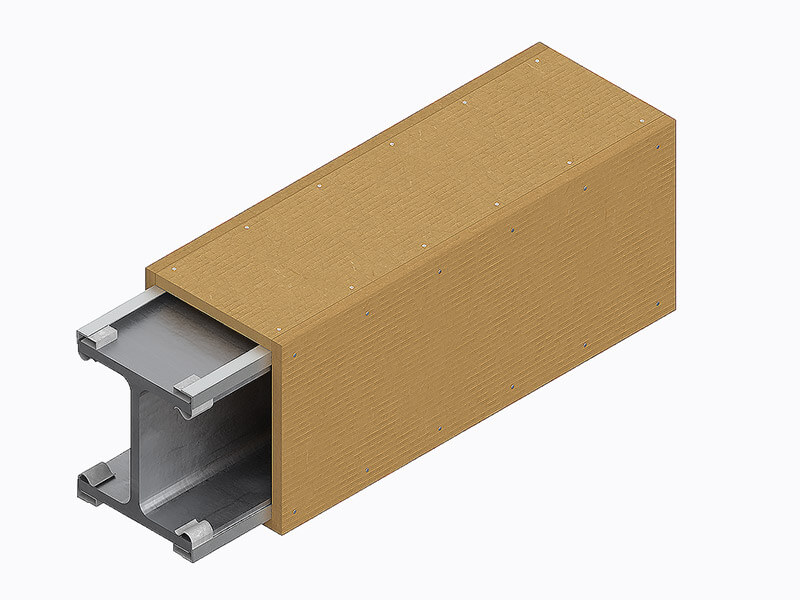

Rigid Board Performance Overview

Product Testing

All of the products that we offer have undergone rigorous testing by both ASTM and Underwriters Laboratory (UL) to verify their physical properties and determine their performance during a fire. UL fire tests are conducted on various construction assemblies and data is used to extrapolate a required thickness for each individual steel member based on the required hourly rating. Selection of the proper UL design for each project is critical in insuring that a building meets codes.

Technical Data

Product Information

- Density 9 pcf

- Dimensions 2' x 4'

- Thickness 1" to 4-1/2"

UL Designs (Floor/Ceiling)

- Floor Assemblies D301, D915

- Floor Beams N308, N309

UL Designs (Column)

Column X314

Manufacturers and Products

United Spray takes pride in working with the best available materials and manufacturers

For a full list of spray foam used

Fireproofing SolutionsPREVIOUS

Intumescent CoatingNEXT

Applied Fireproofing