General Information and FAQ

What is Spray Foam

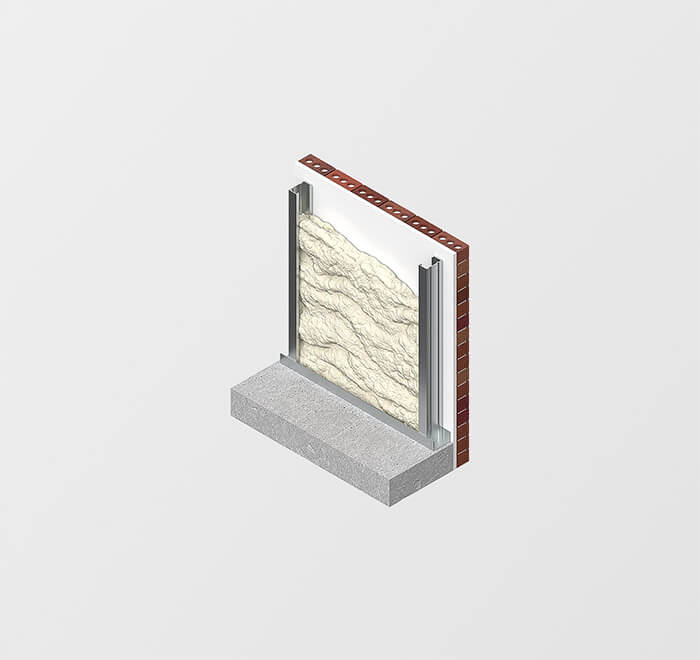

Foamed-In-Place Insulation or Spray Foam as it is commonly referred to, is a newer solution to an age-old need of providing separation of interior and exterior environments including heat, air and moister transfer. Spray Foam Insulation can be used for a verity of functions and provides benefits that would have required the use of more than one product in the past, Spray Foam can be used as an air barrier, vapor barrier and high R thermal insulation all in one. The ever-increasing costs required to condition an interior space as well as the conscious shift to conserve energy and minimize our impact on the environment has led to a boom in the Spray Foam market over the last decade. The advancements in Spray Foam equipment and building code shift towards more efficient designs has caused this high- performance product to be specified in more buildings than ever before.

United Spray uses the latest in mobile foam reactor technology to handle jobs of all sizes with ease. Our spray rigs have mounted power supplies and chemical storage capacity allowing us to pull up to any job- site and be spraying within no time. Our team of knowledgeable managers and installers insure our projects run smoothly no matter the size or scope.

Types of Spray Foam

Closed Cell Foam

A dense foam, generally referred to as 2lb foam in building specifications. Close Cell Spray Foam provides one of the highest R/inch insulation solutions in the industry. This class of products provide air/vapor barriers when applied at sufficient thickness and are certified by the ABAA as an approved air barrier product.

Open Cell Foam

A semi-rigid solution, generally referred to as .5lb foam in building specifications. Open Cell Spray Foam has a much higher expansion factor than its closed cell counterpart. This leads to higher material yield and lower costs however this product class boasts a much lower R/inch and does not have Air/Vapor Barrier capabilities.

Thermal / Ignition Barrier

Due to the combustible nature of all plastic foam products, Building codes mandate that all Spray Foam be separated from interior living spaces by a minimum of 15-minute Thermal/Ignition barrier in case of fire. This barrier can be provided with coverings traditional coverings like drywall or by new age and more cost effective solutions like Intumescent Coating or Spray Applied Cellulose Coatings. Due to the combustible nature of all plastic foam products, Building codes mandate that all Spray Foam be separated from interior living spaces by a minimum of 15-minute Thermal/Ignition barrier in case of fire. This barrier can be provided with coverings traditional coverings like drywall or by new age and more cost effective solutions like Intumescent Coating or Spray Applied Cellulose Coatings.

Thermal Rating Requirements

Thermal rating requirements as generally set by the International Energy Conservation Code (IECC). Required ratings are governed by geographical location and which climate zone that area falls in. The United States is broken into 8 zones all with their own rating requirements.

Common Products Used

Spray Foam insulation provides thermal protection for building envelopes. Each product has unique features best suited for individual building needs. Below are a some of the products that are generally found in spray foam specifications.

Closed Cell Products

- HEATLOK HFO PRO

- HEATLOK HFO HIGH LIFT

- HEATLOK ECO

- HEATLOK AIR BARRIER SYSTEM

- Sealtite PRO

- Sealtite PRO One Zero

- Proseal (MD-C-200v3)

- ProSeal HFO

- Proseal LE

- MD-C-200

Open Cell Products

- SEALECTION 500

- DEMILEC APX 2.0

- AGRIBALANCE

- Sealtite PRO Open Cell

- OC No-Mix

Thermal / Ignition Barrier Products

- DC-315 Intumescent Coating

- Ure-K 15-Minute Thermal Barrier

FAQ

WHY DO I NEED SPRAY FOAM

Spray foam acts as a protective layer within a building envelope preventing the transfer or heat in our out of a specific area.

WHICH TYPE DO I NEED

Spray foam needs can vary for each project, reach out to our team today to discuss what product might work best for your needs